Optimal Curing Environment: Breathable Dust Barrier Floor Protection Mats for New Epoxy and Concrete Seals

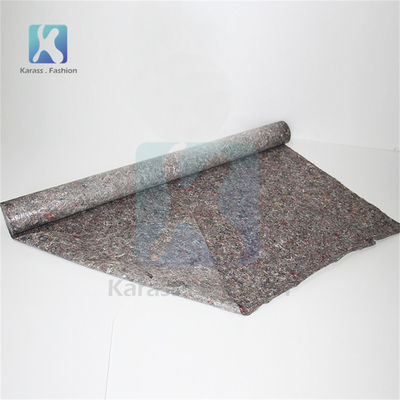

Our Breathable Dust Barrier Floor Protection Mats are a specialized product designed for the unique needs of newly applied finishes that require protection from damage while still needing to "breathe" or cure properly. This mat features a unique composite structure: a durable, soft, non-abrasive synthetic fiber top layer combined with a specialized underside that is permeable to moisture vapor but impermeable to liquid spills. This crucial differentiation allows solvents and moisture vapor from curing coatings (like epoxies, polyurethanes, or concrete seals) to escape, preventing clouding, blistering, or delamination, which are common issues when non-breathable plastic sheets are used prematurely. The top surface provides cushioning against impact and prevents dust and debris from settling into the wet or tacky finish. Ideal for professional floor coating companies, these mats offer a safe walking surface during curing periods, minimizing the risk of irreparable damage to the fresh finish. This technology guarantees a flawless cure environment, balancing protection against physical damage with the absolute necessity of vapor release.

Key Features and Advantages

Vapor Permeable Underside: Allows moisture and solvent vapors from curing finishes to escape, preventing finish defects.

Liquid Impermeable Top: The top layer remains highly resistant to water, paint, and spill ingress.

Soft, Non-Abrasive Fiber: Safe for newly applied and sensitive finishes, preventing scratching and scuffing.

Cushioned Impact Protection: Protects against minor drops and light foot traffic during the curing phase.

UV Resistant: Stable composition allows for use in sunlit environments without degradation.

Fast, Flat Installation: Rolls out quickly and easily without curling, ensuring a smooth temporary floor.

Technical Parameters

|

Parameter

|

Specification

|

|

Material

|

Composite Non-Woven Fiber with Permeable Backing

|

|

Standard Roll Width

|

3ft / 4ft (0.91m / 1.22m)

|

|

Standard Roll Length

|

164ft (50m)

|

|

Permeability

|

High (Specific MVTR rate available upon request)

|

|

Thickness

|

12 mil / 15 mil (Approx.)

|

|

Color

|

White or Light Gray

|

FAQ Section

Q: How do I know when the finished floor is ready for this mat?

A: Consult the coating manufacturer's guidelines. The mat is typically applied after the coating is dry to the touch but before the recommended full cure time, usually within 12 to 24 hours of application.

Q: Can this mat be left down for the full cure time (e.g., 7 days)?

A: Yes, this mat is specifically designed to remain in place for extended curing periods, offering protection without interfering with the necessary off-gassing process.

Q: Does the breathable side need to face up or down?

A: The soft, fiber side should face up to provide cushion and absorb dust. The specialized permeable backing should face down onto the curing floor.

Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!  Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!